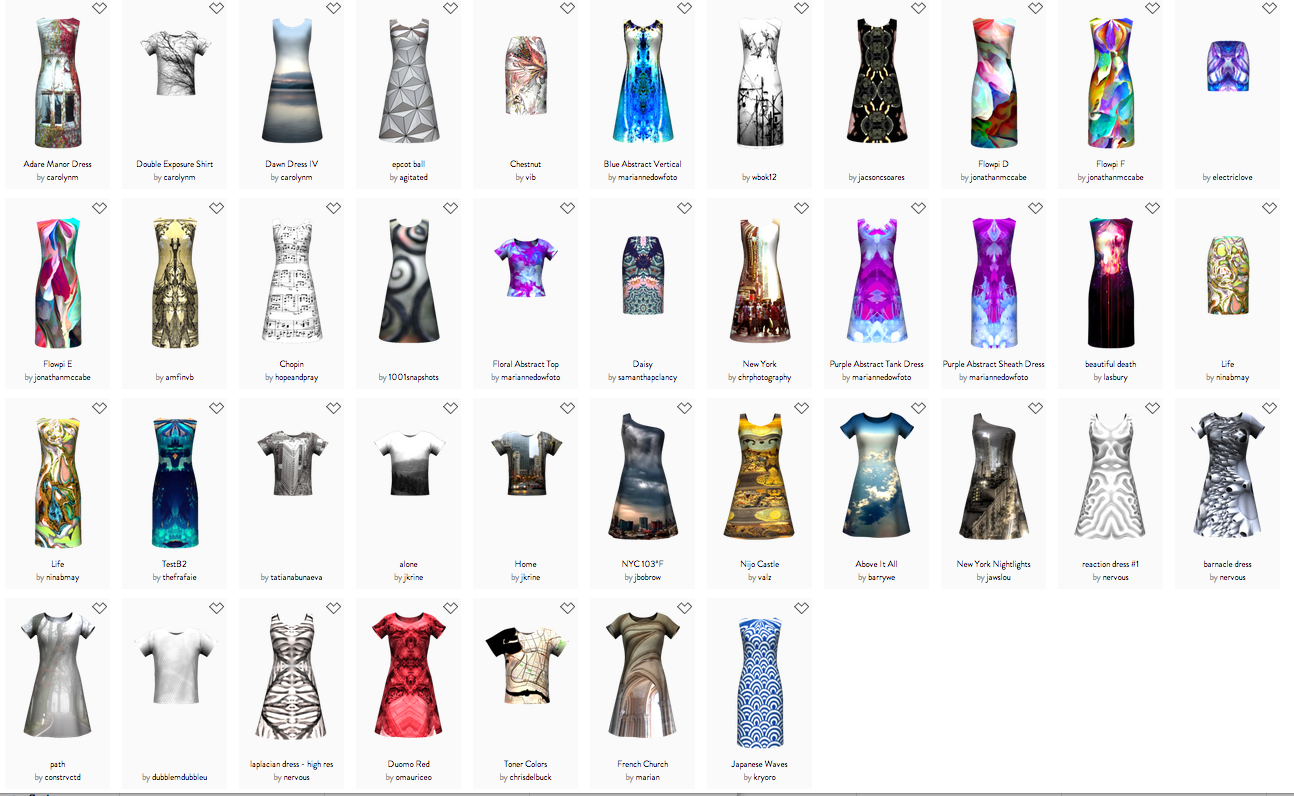

CONSTRVCT is an online destination to create, share, and make fashion designs. Create digital designs in 3D that can be exported to pattern files to create the physical clothing.

CONSTRVCT initially started as a crowd-sourcing concept and made-to-order service, but has evolved to be a platform for digital fashion design. While we worked on our own tech to re-engineer how to make dresses based on 3D CAD, we discovered that there is an apalling lack of accessible software tools to design clothing. So we set out to establish a new standard of digital craft-- easy to use 3D tools to make and share designs.

Our design for constrvct.com draws from Constructivist art, because CONSTRVCT draws upon the same spirit of inventive creative process.

CONSTRVCT is an ongoing endeavor, where we hope to add features to expand the freedom of design that people can achieve.

We are striving to enable a pivotal innovation in design process, where the design interface seamlessly links up to pattern-making and materials. And where anyone in the world can make a design, share it across the web, and that design can be downloaded and made at any point on the globe.

DESIGN PROCESS

We use combined techniques from architecture, animation, and industrial design. First, we create a 3D model of a garment. The 3D model then goes through our parametric sizing system, which generates sizes on demand given a set of measurements. Our code then generates the data to map images across the garment in 3D. This is the distinctive quality of CONSTRVCT prints--An image can be matched perfectly across multiple sewn pieces, for a whole seamless image. This is a design feature that can only be done through our computational process.

Digitally printed fabric is a fundamental design decision on many levels. It allows us to produce a physical product that matches extremely accurately to the design preview online. It allows for an infinite variety in designs even before we enable editing on base silhouettes, and the results are dramatic and distinctive. It also turns any design into an on-demand kit--Just cut on the lines and sew. Digital textile printing is also eco-friendly, as almost all the dye is locked directly to the fabric and thus does not enter into wastewater.

A muslin test, showing the underlying 3D mesh structure